The Green Circle

Marlborough’s economy is built on productive land and water. Viticulture, aquaculture, and forestry drive export revenue, support regional employment, and underpin the long-term value of New Zealand’s food and fibre sector. These industries operate at scale and intensity, delivering premium products to international markets.

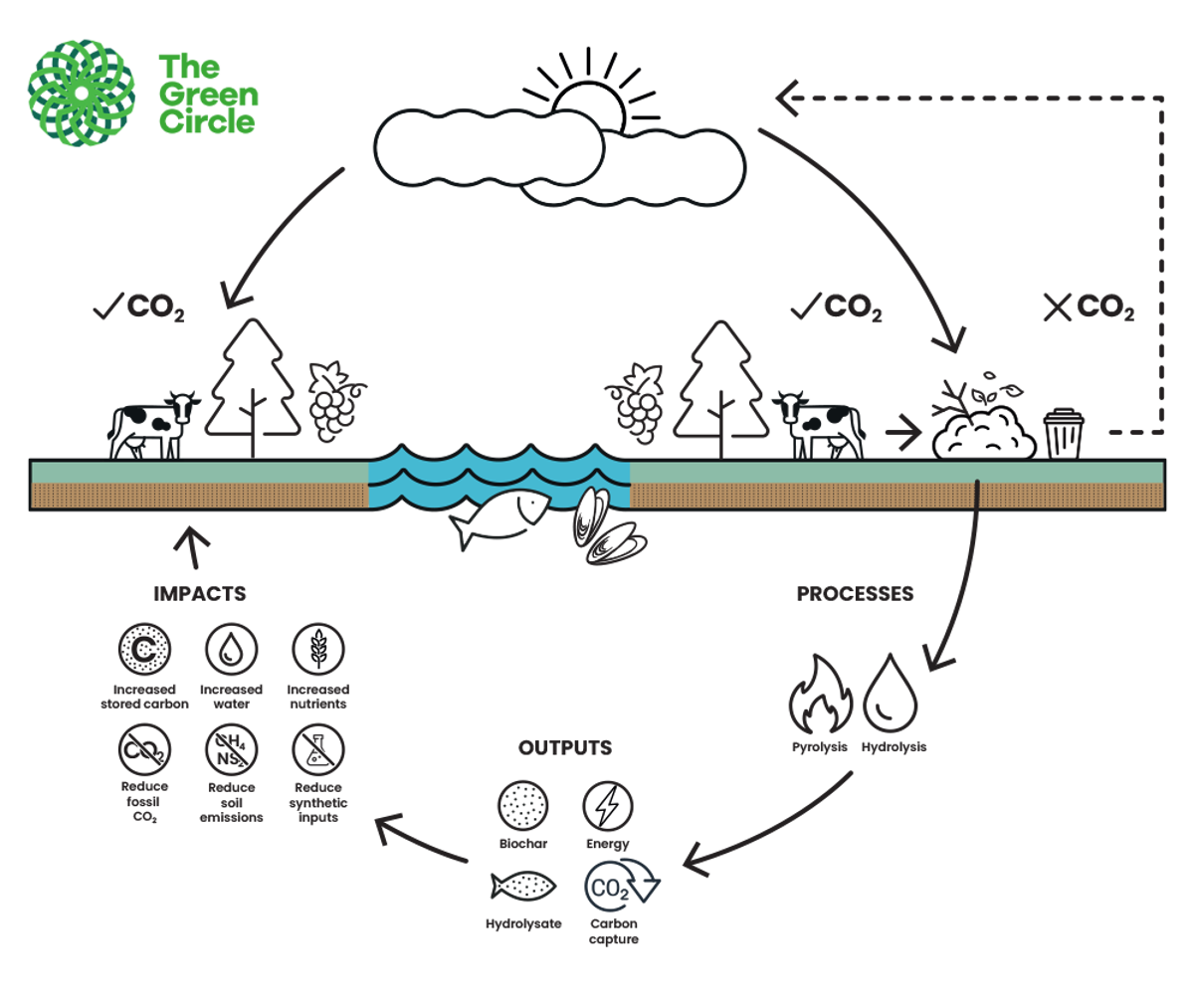

But the scale of production brings an equally large challenge. Across sectors, organic by-products; grape marc, mussel shells, vine trunks, salmon waste, forestry slash, build up in volume and frequency. Most are treated as waste, despite carrying recoverable carbon, nutrients, and structure that could be returned to the land. What’s been missing is practical, scalable infrastructure to turn waste into soil-ready inputs.

The Green Circle is changing that. Its modular pyrolysis systems convert surplus biomass into certified biochar and soil products, delivering circular production at source and building the infrastructure Marlborough needs to align productivity with climate and land-use goals.

Engineering Soil Inputs from Organic Waste

At the core of The Green Circle’s system is pyrolysis, a clean thermal process that converts biomass into stable carbon and energy-rich gases by heating it without oxygen. The process avoids combustion and produces biochar: a carbon-dense, porous material with long-term benefits for soil.

Biochar strengthens soil structure, improves moisture retention, supports microbial life, and delivers enduring carbon storage. Each tonne produced removes up to 3.67 tonnes of CO₂ equivalent. The system powers itself using the gases it generates, requiring no grid connection or external fuel.

What sets the model apart is its delivery. Pyrolysis units are modular, mobile, regionally adapted and designed to operate where the waste is produced. They can be deployed directly at vineyards, aquaculture sites, and forestry yards, or installed at shared hubs to serve multiple producers. This enables clean, on-site processing that fits seamlessly into existing operations.

Biochar outputs are certified, traceable, and independently verified, ensuring environmental performance and proven benefits to soil structure and fertility. Each unit functions as part of the production system, reducing waste while returning carbon and nutrient value directly to the land.

Carbon Removal Certificates (CORs) created during manufacturing are independently verified by Puro Earth and can be traded on international voluntary markets to provide additional revenue and offset carbon liability for industries.

The technology generates a biochar with a carbon content exceeding 90% and produces over a megawatt of excess heat energy that can be utilised alongside an existing boiler or to generate electricity.

Built from Operational Insight

The founders of The Green Circle have extensive experience in farming and environmental systems, which revealed the significant potential within organic waste. Their team contributed strategic and commercial acumen gained from early-stage ventures centred on sustainability and systemic change. Collectively, they created a platform designed to reduce emissions, enhance soil functionality, and deliver lasting value to land-based operations.

In 2024, The Green Circle partnered with Yealands Wine Group to install a pyrolysis unit at its vineyard in Seddon. Grape marc and vine trunks were processed on-site, and the resulting biochar applied directly to the vineyard as part of a multi-year soil trial. The project is now measuring outcomes in soil structure, moisture retention, and vine performance under commercial conditions.

This is the first closed-loop biochar deployment of its kind in New Zealand’s wine industry, using waste generated on-site to enhance productivity in the same location. It shows how circular systems can be integrated into everyday production and aligned to the environmental targets of the industry.

Extending Impact Across Sectors

While viticulture provided the initial testbed, The Green Circle’s platform is now being extended across aquaculture and forestry, two sectors facing similar pressures around waste, emissions, and resource recovery.

The initial pilot project at Yealands has now evolved into a larger initiative. In collaboration with Bragato and the waste industry, this project will provide wineries with a circular upcycled solution for their winery waste, which currently either ends up in landfill or council treatment ponds.

In aquaculture, mussel shells will be processed and combined with biochar for use in horticulture and turf systems, Biochar is also being combined with compost and organic stimulants that support regenerative land management. In forestry, trials are underway to evaluate the use of slash as a carbon-dense input that enhances soil structure on erosion-prone land.

Across all applications, feedstocks are locally derived and processed using low-emission, closed-loop systems. This enables land users to align the use of biochar with their own compliance, certification, or sustainability requirements.

This is a regionally connected infrastructure capable of turning organic by-products into high-performance soil inputs; aligned with Marlborough’s production systems and the region’s broader sustainability roadmap.

Positioned to Scale

The Green Circle’s pyrolysis units adds local capacity to convert waste into valuable soil amendments and measurable carbon sequestration. The system is engineered for scale without compromising its regional fit or operational practicality.

With additional units in development and growing partnerships across Marlborough’s primary sectors, The Green Circle is now positioned to lead nationally in circular, carbon-negative infrastructure. It demonstrates how regional innovation can be converted into applied capability, transforming production waste into productive resources.

This is practical infrastructure integrated directly into Marlborough’s land-based industries, commercially built, impact-verified, and ready to scale. As circular production systems become essential, Marlborough is leading by building resource-efficient infrastructure that lifts productivity, meets sustainability targets, and positions the region for future growth.